Ethernet-APL Adoption will Accelerate Process Automation

By combining high-speed digital communications, power delivery, and simple cabling requirements, Ethernet-APL advances digital transformation.

The industrial process automation industry is slow to change, and rarely excited about new technologies. Our Process & Control July/August 2023 article titled Accelerating Process Automation with Ethernet-APL points out a notable exception to this generally blasé attitude, as users, suppliers, OEMs, and integrators are eagerly anticipating the benefits promised by Ethernet-APL.

Ethernet-APL basics

Standard Ethernet media has already been widely adopted for many industrial automation purposes, but it has lacked the following features needed to best meet unique industrial requirements:

- Two-wire installation over long lengths using standard cables

- Supplying field device power over those two wires

- Providing high-speed data communication over those same two wires

- Ability to deploy in hazardous environments

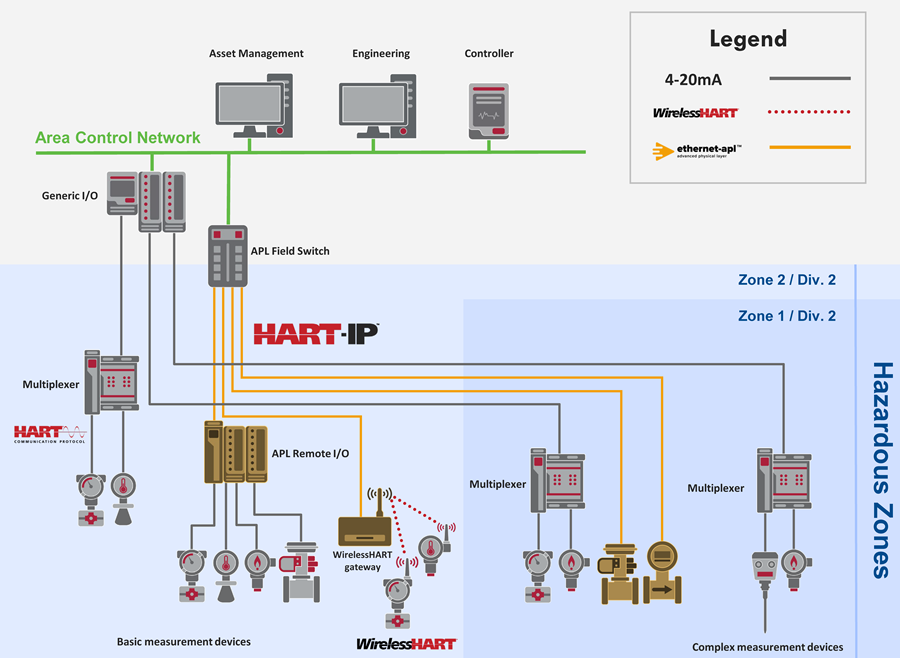

Ethernet-APL is a 10 mbit/sec physical layer, supporting Ethernet automation protocols such as HART-IP, PROFINET, and EtherNet/IP. It will be possible for non-traditional devices to share the same cabling structure with typical field transmitters, such as a video camera on the same network as a pressure transmitter. Personnel trained in IT technologies will be comfortable working with Ethernet-APL, and installation and ongoing support are very simple and cost effective.

Architecting Ethernet-APL

Ethernet-APL relies on powered field switches, which convert plant Ethernet—connected to controllers or other computing assets—to intrinsically safe Ethernet-APL, while also injecting power into the physical layer to meet the needs of remote I/O, instrumentation, and other field devices. Cable runs can be up to 1,000 meters long.

The architecture provides a simple way to get started with Ethernet-APL by installing just two cables and two pieces of expandable infrastructure. Traditional field instruments can be connected to Ethernet-APL remote I/O, and the architecture can be expanded as new devices become available and user needs grow.

While it is possible to re-use some existing cabling, designers will need to perform cabling testing first, and they should consider working with experienced suppliers and qualified installation professionals to ensure successful deployment.

Digital transformation, accelerated

Many end users, suppliers, OEMs, and systems integrators already rely on standard Ethernet technologies in the traditionally conservative process automation industries. However, change and even a degree of excitement are building for Ethernet-APL.

Even within the disciplined process automation industry, it is possible for new technologies to spark excitement. Ethernet-APL is a prime example.

With the ability to seamlessly extend high-speed communications, power, and intrinsically safe connectivity to field devices, Ethernet-APL is positioned as the communications technology of choice for both new and retrofit digital transformation projects.