UNDERSTANDING SEMANTIC IDENTIFICATION

One of the principle benefits of PA-DIM is the ability to “map” protocol specific parameters to globally standardized terms for these parameters.

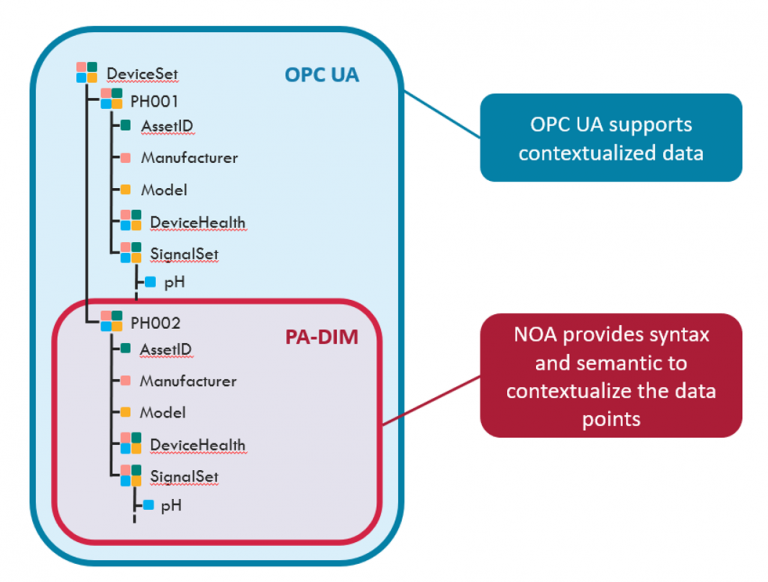

PA-DIM is a manufacturer independent Information Model with a structured hierarchy for standardized data access for devices. A Device (Asset) has Set of Signals (Functions) e.g. Process Variables, which are based on OPC UA Part 100 Devices (DI-model). PA-DIM re-use IVendor-, ITag- Nameplate and IDeviceHealth- Interfaces from DI. In addition, PA-DIM defines IAdministration- and ISignalSet- Interface, so that it is reusable by other Information Models. All parameter are defined in IEC 61987 CDD with Semantic ID (IRDI), which ensures that parameter can be easy re-used between different software tools and protocols.

Annother main part is the SignalVariableType, which is an extension of OPC UA Part 8: Data Access an describes analog and discrete variables including its simulation. This variable can be used at any object also from oter Information Models. The PA-DIM SignalType Object uses the SignalVariableType and adds the SignalTag and specific methods like ZeroPointAdjustment or AutoAdjustPositioner.

PA-DIM Simplified Data Access

- Manufacturer Independent

- Sorted

- Structured Hierarchy

- Prioritized

- Mapping can be understood by standard interface tools

Watch the recording of the presentation by Achim Laubenstein (FieldComm Group) and Frank Fengler (ABB) who provide an overview of the PA-DIM specification which is the OPC UA information model for process automation devices, including semantic identification.

ADDITIONAL RESOURCES

Check out these resources, including brochures, technical papers and other documents.